As human beings are superior of all the other living

organisms on the earth, it’s our prime duty to keep the earth pollution free

and sustainable for future generation. But now a days, the most worst case

scenario is that, the pollution on the earth is increasing day by day.

Pollution on earth can be of different types but the pollution that bypasses

all the other pollution and holds a significant place of being primely

concerned is the pollution caused by the materials made up of plastic.

If we look upon certain facts given by some prominent

institutions then as per CPCB(Central Pollution Control Board), India generates

55 million tonnes of municipal waste annually, of which only 37 percent is

treated. Out of the untreated waste, most of them were plastic materials.

As per United Nations Environment Programme(UNEP), the

amount of plastics in the oceans has been estimated to be around 75-199 million

tonnes at present time which is projected to nearly triple by 2040.

After having a look on all these matters of concern,

we have decided to create something that will not only adds towards

sustainability of the environment and the earth, but will also provide us

humongous profit at the same time.

And Therefore, we have decided to create Paver blocks with the help of the most polluted material on earth that is the Plastic Materials.

Which

category of plastic we are dealing with ??

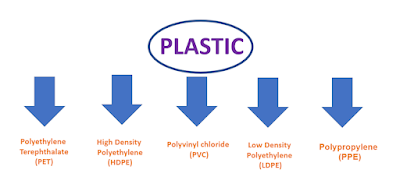

Before discussion the exact process of manufacturing and other things, we must know what types of plastic materials we are dealing with for making the paver blocks and for that we must know the different categories of plastics.

Plastics other than these types of plastics are very hard to breakdown and recycle and hence are known as single used plastic materials. These types of plastics are not accepted by recycling centers and becomes the prime reason of pollution in Land Fields and Water Bodies.

These plastics basically includes items like

disposals, plastic bags, straws, coffee stirrers, soda, water bottles, packet

of chips, etc.

From all

the above discussion, we came to know that it is the

single used plastic that is too much harmful and also polluting our land field

and water bodies, it is the ultimate problem that requires an immediate

solution.

And as we already stated earlier, every solution has

an opportunity to become an startup, here the business that we are dealing with

is

Making Paver Blocks Bricks by Using Single Used Plastic

Our

Moto –

As we are using something that is polluting our environment and also can’t be recycled easily, it is definitely a step taken by us to make the earth sustainable for future generation and here’s our moto comes out –

A

Step Towards Sustainability,

Making

Earth Sustainable For Future!!

Brand Name –

Why

“BAGS” as Brand Name??

As we all know, the brand name should be very brief,

short and easier to pronounce, the brand name “BAGS” fits in all aspects.

Moreover, as most of the single used plastics are in the form of plastic carry

bags, it will be much more easier for the people to know what this startup is

all about and also to understand the overall moto of the company.

Another important fact taken into consideration while

deciding the brand name is that, if we split the brand name it will further

turns into our own names (members of this startup) :-

B - Ben

A - Anjumoni

G - Gyanesh

S – Sunidhi

Further, the Tag Line “RECYCLE

IT” indicates that we are recycling the plastic carry bags (That’s

however can’t be recycled otherwise), which is again a quite appreciable thing.

Company

Name –

BAGS

PAVER BLOCKS PVT. LTD.

How

does the Final Product will look like??

First step in the manufacturing process is to putting

the plastic waste in the dust cleaning machine. The dust cleaning machine

cleans the raw plastic waste, thereby removing all the sand and dust particles

and brings it in a cleaner form for further processing.

After cleaning the plastic waste, the next step is the

Shredding of the plastic waste. It basically means cutting down the plastic

waste into much more smaller form, basically into fine particles (in the form

of powder, we can say) for the further processing of the same.

After Shredding of the plastic waste, the next step is

the mixing of plastic waste into the concrete element (Basically mixing it with

other raw materials) for making the paver block bricks with the help of a

mixer.

In the next step, the mixer of concrete and shredded

plastic are given different types of shapes with the help of different types of

moulds (Ranging from Zig Zag Moulds, Checkered Shaped Moulds, Dumbbell Shaped

Moulds etc.).

After moulding, they are passed through a vibrating

table so that they would properly be fit into the mould, removing any bubbles

gaps in them, to come out in the most desired shape after it is being de

moulded.

While passing it through the vibrating table, one can

also add colour in the paver blocks (If wants to), and leaving it in the

vibrating table itself for proper mixing of the colour.

Once the vibrating table process is being completed,

the paver block bricks are required to be De Moulded after 24 hours and have to

stock it in the stocking area.

In the next step, we have to leave the De Moulded

paver block bricks in the natural sunlight for around 3 weeks (21 days) so that

it will gain some strength, leading to not breaking it so easily.

After the completion of 21 days, now the paver block

bricks are absolutely ready to put into use.

Where

These Bricks are Used??

Paver blocks made using plastic materials have several

potential uses, including:

Walkways and Driveways:

Paver blocks made from plastic materials can be used to create durable,

attractive walkways and driveways that are resistant to cracking and other

types of damage. They can withstand heavy foot and vehicle traffic, making them

ideal for outdoor areas.

Landscaping: Plastic

paver blocks can be used to create attractive and functional landscaping

features, such as retaining walls, garden edging, and raised garden beds. They

are lightweight and easy to install, making them a popular choice for DIY

landscaping projects.

Patios and Outdoor Living Spaces:

Plastic paver blocks can be used to create beautiful and functional patios and

outdoor living spaces. They come in a wide range of colors and textures, making

it easy to create a customized look that complements your home and landscaping.

Erosion Control: Paver blocks

made from plastic materials can be used to prevent erosion and soil loss in

areas that are prone to erosion. They can be used to create terraced slopes,

erosion control channels, and other erosion control features.

Green Building: Plastic

paver blocks can be used in green building projects as an eco-friendly

alternative to traditional concrete pavers. They are made from recycled

materials and are recyclable at the end of their useful life, making them a

sustainable choice for construction projects.

The use of plastic waste in paver blocks is a relatively

new innovation that offers several benefits, including reducing plastic waste

and providing an affordable, durable building material. The future prospects of

paver blocks made by using plastic waste are positive and likely to remain so

for the following reasons:

1.

Growing concern for the Environment:

As people become more environmentally conscious, there is an increasing demand

for sustainable building materials that reduce waste and carbon footprint. The

use of plastic waste in paver blocks is a creative solution to this problem,

making it an attractive choice for eco-conscious consumers.

2.

Cost-effectiveness:

Paver blocks made from plastic waste are generally less expensive than

traditional concrete or asphalt pavers. This makes them a more affordable

option for homeowners, businesses, and municipalities looking to reduce their

building costs.

3.

Durability:

Paver blocks made from plastic waste are highly durable and can withstand heavy

foot traffic and extreme weather conditions. They require minimal maintenance

and are long-lasting, making them an ideal choice for outdoor spaces.

4. Customizability: Paver blocks made from plastic waste can be molded into various shapes, sizes, and colors, providing a wide range of design possibilities. This makes them an attractive option for designers and architects looking to create unique outdoor spaces.

--